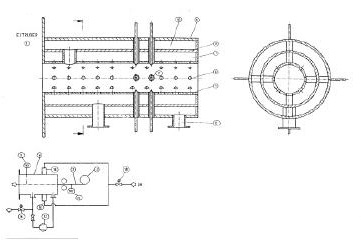

Extruded plastic sections are cooled without contact in a recirculating gas at very low temp. The gas is in counterflow to the extrudate and can be brought to the required temp. at the end of the cooling section by the addn. of liquified gas, independently of the speed or quantity of extrudate.

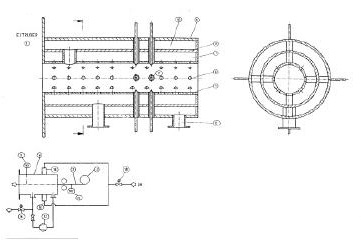

The temp. profile can be regulated by the gas temp. and/or the prod. temp. An extruder feeds a cooling section consisting of concentric tubes. The inner tube has graduated jets to ensure that the extrudate does not contact the walls. Low temp. nitrogen is supplied to the inner annular space and leaves in counterflow through the outer annulus to be recirculated.

The temp. is controlled by injecting liq. nitrogen through jets. In the prodn. of surgical drain tubes the extrudate was at 145 deg.C and was cooled by 100 m3/h. of nitrogen at a mean temp. of minus 100 deg.C. USE/ADVANTAGE - The cooling method has a very steep temp. gradient and is independent of throughput